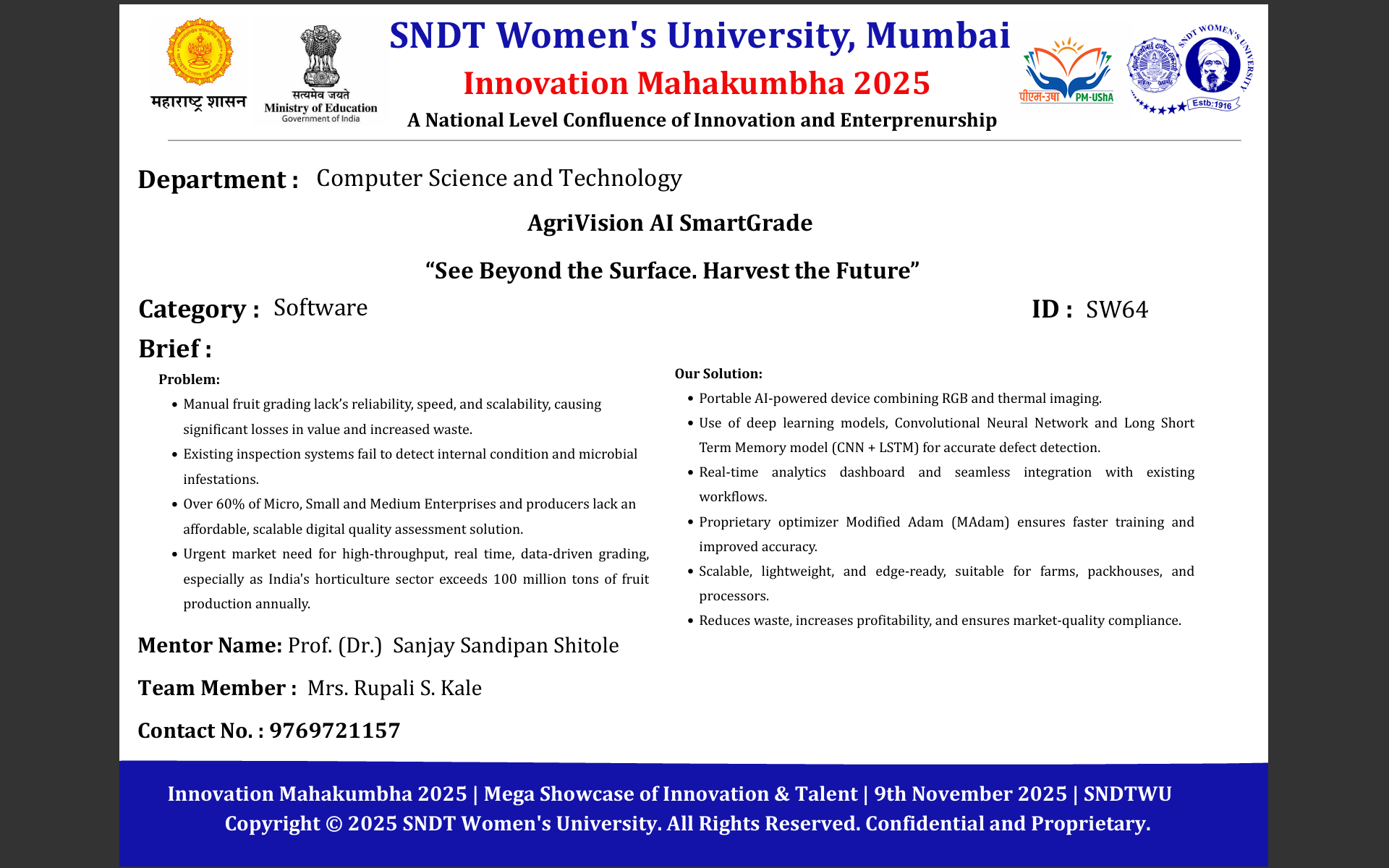

AgriVision - AI SmartGrade

Innovator ID

SNDMAC023

AI-enabled portable fruit grading system using RGB and thermal imaging to improve quality, reduce waste, and increase farmer profitability.

Fruit grading in India is largely manual, slow, subjective, and inconsistent, leading to significant post-harvest losses and reduced income for farmers. Current grading systems cannot detect internal defects or microbial infection, resulting in high rejection rates at export quality checks. Small and medium-scale producers lack access to affordable automated grading technologies, limiting market competitiveness. There is a strong need for a reliable, scalable, and cost-effective AI-based fruit grading solution that improves accuracy, reduces waste, and ensures fair pricing across the value chain.

Portable AI device combining RGB and thermal imaging to detect both surface and internal fruit defects. Deep learning (CNN + LSTM) predicts fruit grade in real time, enabling standardized quality sorting. Reduces waste, increases farmer profitability, and improves export quality compliance.

Farmers, Farmer Producer Organizations (FPOs), fruit packhouses, cold storage units, exporters, and processing industries who require accurate and consistent fruit grading. Agricultural cooperatives and mandis for fair pricing, and agritech companies, inspection agencies, and government horticulture programs for quality assurance and large-scale post-harvest management.

AgriVision AI SmartGrade ensures accurate and consistent grading, reducing post-harvest losses and improving selling prices for farmers. Exporters benefit from reduced shipment rejection and higher international market acceptance. The device automates quality assessment, saving labor time and cost. With real-time grading and data analytics, businesses can optimize operations, enhance traceability, and ensure compliance with horticulture standards. The value gained through waste reduction and higher market value outweighs the investment, making it cost-effective across the supply chain.

We Would Require Support In the Following :

Technical and Product Development Support; Mentorship and Expert Guidance; Funding and Financial Assistance; Infrastructure and Prototyping Facilities; Networking, Collaboration, and Investor Connect

Capital to achieve the desired outcome, we would require

₹10–25 L, unclear

And would be required for

Prototype Development Support; Technology and Digital Infrastructure Funding; Pilot Testing and Field Trial Support; Business Model & Market Access Support

Expected Return Should Be in:

Less than 3 years